Introduction

Awhile back we taught you the basics of pulling a golf shaft. You can read that post here if you want. Well, the general process for pulling a graphite shaft is just about the same, but there are a few key differences. You need to take more care and HAVE to use a shaft puller. Otherwise, your new fancy and expensive exotic shaft could be at serious risk for major damage. We’ll teach you how to properly pull a graphite shaft in this post.

Supplies Required

In order to pull a graphite shaft both safely and successfully, there are a few required tools. It’s important to know that if you’re pulling a graphite shaft, there is a big risk of damaging the shaft if you don’t use the proper tools. Below are my recommendations for what you will need:

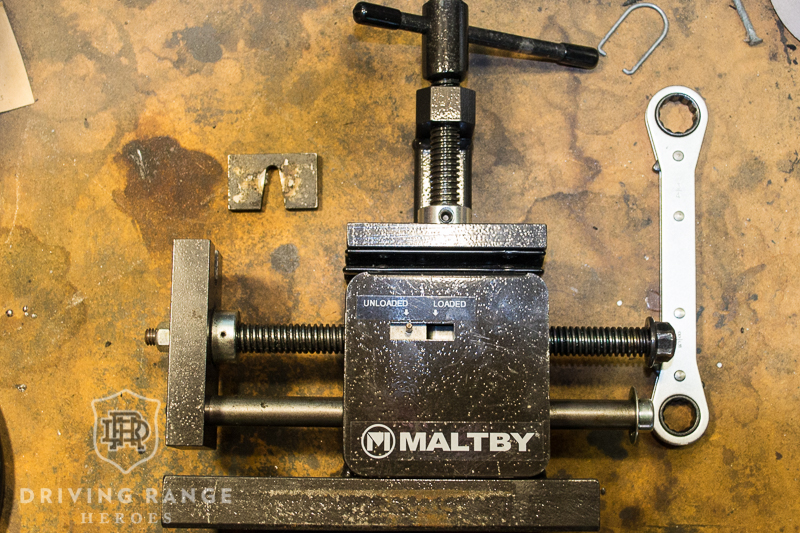

- Shaft puller: This will allow a constant pressure to be put on the club head as the epoxy is heating. Additionally, this will pull the head in a constant straight direction in order to avoid damaging the shaft. By not pulling the shaft perfectly straight, you will have a high risk for catastrophic failure with graphite. The shaft puller removes that risk. There are a lot of options out there, but I advise investing in a good quality shaft puller that has good reviews. 1) They’ll last longer. 2) They will be easier to work with and do a better job.

- Hosel protector: Most decent shaft pullers will come with one of these, but if they don’t, get one. This goes between the puller and the hosel so the shaft puller will put the pressure on the protector plate and not the club head directly. Others may think this to be somewhat unnecessary, but I support its use. ESPECIALLY with graphite.

- Vise: If you don’t want to permanently mount your shaft puller to a workbench, make sure you get one that’s vise mountable. Obviously you’d then need a vise to put it in. The vise is a clutch tool in at-home clubmaking so it’s worth having one around.

- Heat Source: Your standard best options are a heat gun, a propane torch, or MAPP torch. You will need these to apply constant heat at the hosel to break down the epoxy so the head will separate from the shaft. Most seasoned club builders will use a propane torch in order to minimize amount of time exposed to heat. MAPP will break the epoxy down faster, but it gets a lot hotter and I’ve ruined a few shaft adapters with it because of the higher heat.

- Heavy Duty Work Gloves: Part of using heat to pull clubs apart is a hot club head and/or shaft. I like to have some gloves around to quickly handle any hot components. Note, I said quickly. Quick enough to grab a head or adapter and move it to a safe location. If you hold a scorching hot metal component long enough in those gloves, you’ll feel it.

There are other useful items to assist in this process, but these are the basics and should be good enough to get you started.

How To Pull a Graphite Shaft

Making sure you use a safe technique is the most crucial portion of pulling a golf shaft. Failing to do it in a correct fashion could result in that slick $400 aftermarket shaft becoming a $400 piece of garbage. In the interest of making the process easy to follow, we’ll lay it out in bullet point fashion. Note, if you are pulling a shaft that has a shaft adapter, you may choose to remove the clubhead prior to doing the pull and just pull the adapter. That’s generally perfectly fine.

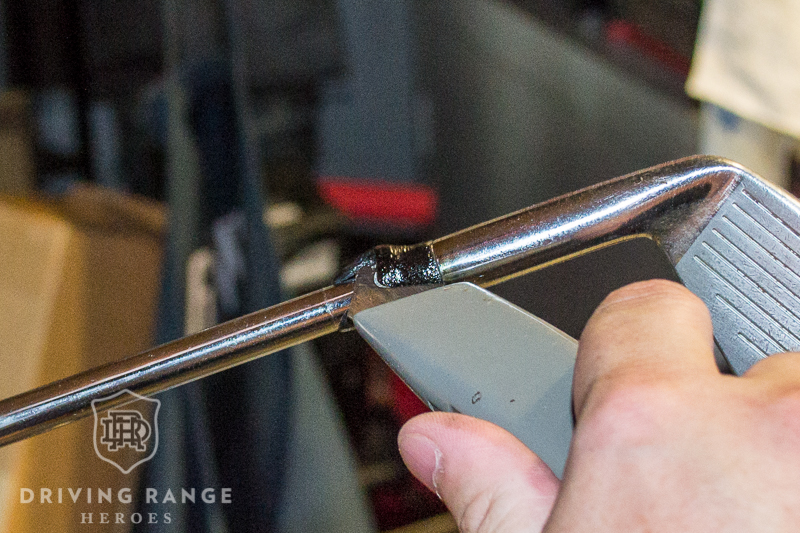

- Remove the ferrule. This isn’t necessarily a must, but it makes life cleaner and easier. This can be done by applying heat with your heat gun or torch until the ferrule is soft enough to cut off with a hook blade. BE CAREFUL ON GRAPHITE SHAFTS! You don’t want to dig into the graphite and damage the shaft…especially at the tip. Also, sometimes the ferrule can be tough to remove on some of these adapters (like Callaway). It’s not unheard of to just let the shaft puller push the ferrule off with the adapter.

- Tightly secure shaft in the shaft puller. If pulling a graphite shaft, you have to have a little touch. You need to clamp down tight enough that the shaft doesn’t just slide while the puller is pushing against the hosel. If you clamp down too tight, you could crack the shaft. Unfortunately, you will likely do this to a few shafts at some point. Be mindful of ambient temperatures. If it’s too cold, the shaft will be more brittle and crack easier.

- Apply pressure to the hosel. This is where you place your hosel protector on the shaft between the head and the puller, then crank the shaft puller until tension is applied. I like to use something that has a tension indicator so you know how much tension is applied and can see if it changes at all. The shaft puller I use applies a constant pressure that will release when the epoxy breaks down and will push the club head off nice and straight.

- Apply heat (pulling the shaft). Now that your shaft is in the puller with tension, all that’s left to do is apply heat at the hosel or adapter to break down the epoxy. Like anything using heat, you want to keep the heat constantly moving around the whole area. Failing to do so could cause cosmetic blemishes to the club or shaft, and even cause permanent structural damage in areas where too much direct heat was applied for too long. After enough heat is applied, the head will become loose and the shaft puller will push it straight off the shaft. DON’T FINISH REMOVING THE HEAD BY HAND. Though the epoxy is loosened, you still want to let the shaft puller push the head all the way off so as not to damage the shaft at the last minute.

“Pro” Tip: Once you get used to this process, I’d suggest a propane torch over heat gun. The torch provides more precise heat application and higher temperatures which means the shaft and club head will experience less time under heat stress and less risk of damage. Your pull will also go quicker. The risk is that if you don’t know what you’re doing with the torch, you may have way too much heat and too concentrated, thus damaging your equipment.

At this point, your club head should be removed. Over multiple projects, you will find that some clubs come apart easier than others. I can only think of one time I was unable to actually pull a shaft using this technique. Depending on the epoxy used, the age, and a variety of other variables, some clubs will require more heat and time under pressure than others. Just be smart and safe with the work to avoid any catastrophes.

Final Thoughts – Pulling a Graphite Shaft

Once you have the correct tools, and a little knowledge, pulling a graphite shaft is pretty easy. For me, it was one of those things where I just needed to have the guts to jump in and get my hands dirty. Between a writeup like this, maybe a Youtube video or two, I was set and figured it out fairly quickly. Of course, I ruined a shaft or two learning in the very beginning, but the education was worth it and they weren’t that expensive of shafts. This skill will prove useful if you’re a big gear tinkerer, or just want to be able to save a decent chunk of change being able to do this yourself.

How NOT to Pull a Graphite Shaft

I mentioned a few times that if you don’t pull a graphite shaft properly, you’re going to have problems. If you try and twist off a head from a graphite shaft, this happens:

Needless to say, that’s no good. It also doesn’t take much heat or force for that to happen. This is why it’s imperative to use the proper tools and techniques. (Special thanks to the shaft that sacrificed itself for this example.)

Here’s a video if you want to see the damage in action.

Bill, those last few pictures of the shafts being ruined is the stuff nightmares are made of. Good post and those last few pictures will make sure I take EXTRA CARE.

Ha, tell me about it. It was fun to do for the post though!

I use a “Spring Loaded” shaft puller to pull shafts because it applies pressure on the head until it is ALL the way off the shaft. As because the pressure is there from the start, as soon as the epoxy starts to breakdown, the pressure will start to remove the head right away, NO DELAY.

I also only use a Butane mini torch to heat the head as Propane can get too hot and a heat gun is not hot enough and the temp will vary as the gun heats up.

I’m a big proponent for spring loaded. That’s what I use too.

Why don’t you just say “take it to a golf shop”.

Yep, that definitely captures the spirit of this post and why people would be reading it in the first place. Good point.